Apa perbedaan antara kabel karet dan kabel PVC?

2025-12-23 16:22When selecting a cable for any application, one of the most fundamental decisions is the material of its outer sheath and insulation. Two of the most common contenders are Polyvinyl Chloride (PVC) and various forms of Rubber (typically EPR, CSPE, or Silicone). This isn't merely a cosmetic or cost choice; it's a decision that determines the cable's flexibility, durability, environmental resistance, and safety profile. Understanding the core differences between rubber and PVC cables is essential for specifying the right product to ensure longevity and reliability.

The Core Difference: Thermoplastic vs. Thermoset

The most fundamental distinction lies in their molecular behavior when heated.

PVC is a Thermoplastic: This means it softens when heated and hardens when cooled, a process that is reversible. This property makes it easy to manufacture and recycle but imposes limits on its high-temperature performance.

Rubber (EPR, Silicone) is a Thermoset: During a curing process (often using heat or radiation), the polymer chains form permanent, cross-linked bonds. Once set, a thermoset material will not melt or flow when reheated; it will ultimately char and degrade at very high temperatures. This structure gives it inherent stability under thermal and mechanical stress.

Head-to-Head: A Property Comparison

| Property | PVC Cable | Rubber Cable |

| Flexibility & Elasticity | Stiffer, especially in cold temperatures. Can become brittle over time as plasticizers migrate. | Excellent, elastic flexibility even at low temperatures. Maintains shape after bending/twisting. |

| Temperature Range | Standard: -5°C to +70°C. Special grades up to 105°C. Softens at lower high temps. | Wider range. Standard EPR: -40°C to +90°C. Silicone: -60°C to +180°C+. |

| Environmental Resistance | Good resistance to water, acids, and alkalis. Poor resistance to oils, fuels, ozone, and UV (unless specially formulated). | Superior overall. Excellent resistance to oils, fuels, ozone, UV, and chemicals. Ideal for harsh conditions. |

| Flame Retardancy | Naturally flame-retardant due to chlorine content. | Often requires additives to achieve similar flame retardancy. Special grades (like CSPE) are excellent. |

| Smoke & Toxicity | Produces thick, black, toxic, and corrosive smoke (HCl gas) when burned. A major safety concern in confined spaces. | Halogen-free options (many elastomers) produce less smoke, and it is non-corrosive. |

| Abrasion & Tear Resistance | Good, but can be cut or nicked. | Generally superior, with a tougher, more resilient jacket. |

| Cost & Weight | Lower cost and lighter weight. | Higher cost and often heavier. |

The Ideal Domains: Where Each Material Excels

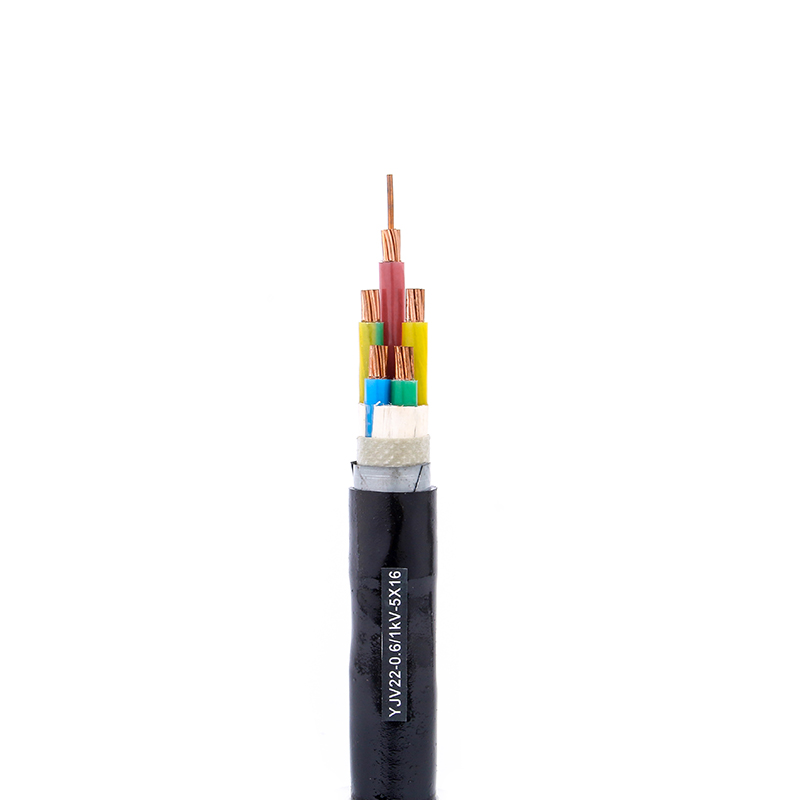

Choose PVC Cable When:

Cost is a primary driver for fixed installations.

The environment is dry, indoor, and stable (e.g., behind walls, in conduits, office buildings).

The application is for general-purpose wiring, house wiring, or low-flex control panels.

There are no significant exposure risks to oils, chemicals, or extreme temperatures.

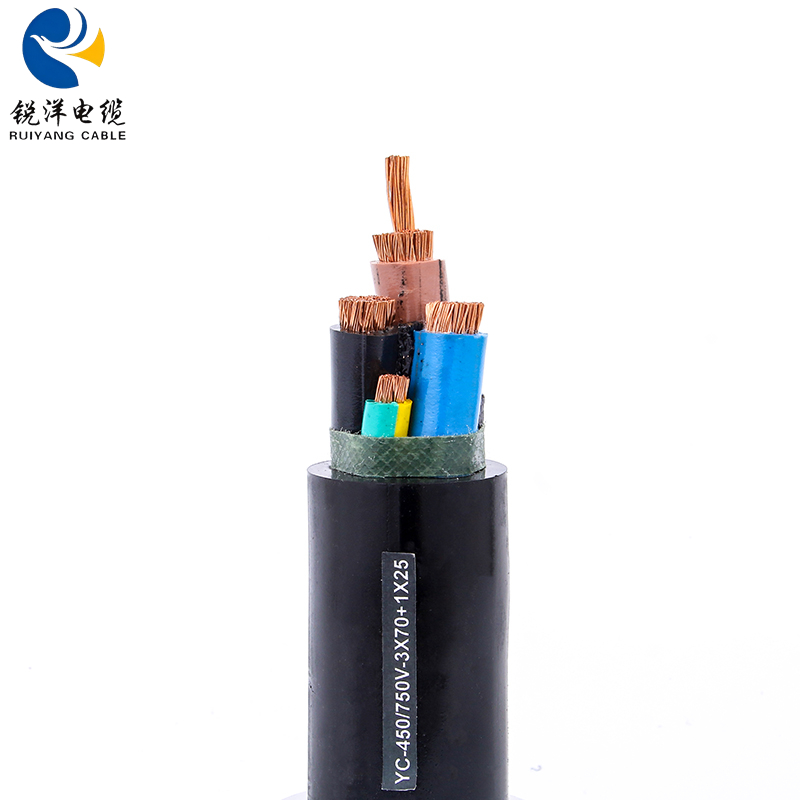

Pilih Kabel Karet Saat:

Kabel akan mengalami tekukan, pembengkokan, atau pergerakan terus-menerus (misalnya, pada gulungan kabel, lengan robot, mesin pertambangan, peralatan panggung).

Lingkungannya keras: di luar ruangan, di pabrik industri, terpapar minyak, pelarut, ozon, atau perubahan suhu yang drastis.

Diperlukan fleksibilitas pada suhu rendah (misalnya, penyimpanan dingin, aplikasi luar ruangan di musim dingin).

Peningkatan keselamatan untuk ruang tertutup (seperti kapal, kereta api, terowongan) menuntut kinerja rendah asap dan bebas halogen.

Aplikasi ini ditujukan untuk peralatan tugas berat, kabel las, atau catu daya portabel.

Pilihan antara karet dan PVC bukanlah tentang material mana yang lebih baik, tetapi mana yang sesuai untuk lingkungan operasional dan tuntutan mekanis.

PVC adalah pilihan yang ekonomis, andal, dan serbaguna untuk instalasi standar dan tetap di mana kondisi yang keras bukanlah faktor penentu. Anggap saja ini sebagai pilihan utilitas standar.

Karet adalah bahan khusus yang tahan lama dan fleksibel, dirancang untuk bertahan dari benturan fisik, paparan bahan kimia, dan siklus termal yang berat. Anggap saja sebagai pilihan tugas berat untuk industri atau kendaraan.

Memilih material yang salah dapat menyebabkan kerusakan kabel sebelum waktunya—retak, mengeras, melunak, atau kerusakan isolasi—yang mengakibatkan waktu henti, bahaya keselamatan, dan biaya penggantian yang lebih tinggi. Dengan mencocokkan material kabel dengan masa pakai operasionalnya di dunia nyata, Anda memastikan instalasi yang aman, andal, dan hemat biaya.

>>> Grup utama Ruiyang Kabel Berselubung Karet